EckyH

Senior Member

- Location

- Nottuln, North Rhine-Westphalia

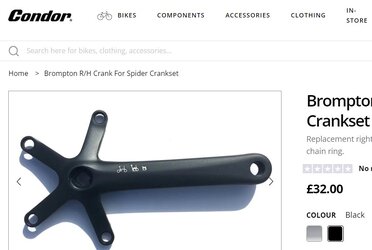

Roughly six years ago the right Truvativ Rouleur crank on my commuter bicycle broke at the pedal eye with a similar fracture surface: dark and relatively smooth like here on the right side and rough and light at the left side. The beginning was a hairline crack, very hard to notice on a silver crank and even harder to see on a black one. The only hint in my case was a faint creaking noise from the pedal area - where the pedal has had it's own creaking crack. Therefore I wouldn't blame the owner of this bicycle.I just saw this pop on Faceboast, don’t know the whole back story, ie rider weight/bike luggage weight etc, but pretty sure it shouldn’t do this.

View attachment 705830

The crank broke suddenly and I hit the ground fairly hard. The result was a light concussion - and a broken helmet.

I hope the rider of this bike had at least as much luck as I had.

E.