So this is why changing chains as they wear is key to keeping chainrings/cassttes in good order? I suppose you might say it isnt so much the "stretch" that is the issue but the poor fit that it causes?

Where does the "stretch" come from? is it true stretch or is it from wear in the rollers? As another poster has pointed out over the length of a chain it can be quite significant.

Stretch is a swearword. Say elongate.

You are right, the elongation in itself doesn't weaken the chain. The chain elongates by wear on the rivets. It is not the rollers that run on the rivets but their bushings. The bushings wear correspondingly on the inside. Only every second link elongates.

It is the mismatch in pitch between chain and sprocket that causes the problems and the problems are not the same for a driven and driving sprocket. Further, the problems are completely different for a driven sprocket with insufficient wrap and a spring-loaded tensioner a.k.a. a rear derailer.

Here are three rivets. The one on the left is new. The second one has worn enough for the chain to elongate by 0.5% and the third one is off a chain that has elongated by 1%. Incidentally, if you look at how the peen broke off the nearsides of each rivet you know why a rivet cannot be pushed out and re-used.

It is impossible to photograph the wear on the bushing, so here's an graphic from Shimano, showing bushing flank wear.

Here's some roller and bushing detail

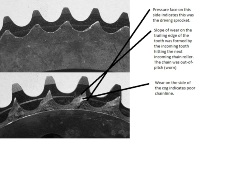

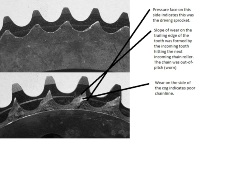

This pin is super worn, probably 2% This is just about impossible to achieve on a cassette bike because all the sprockets don't wear at the same rate and the chain will skate on all but say the top and bottom one. This is off a singlespeed chain. Once the chain is worn like this, then the chainring (driving sprocket) shows wear beyond the shark fin stage and into the shark tooth stage.

Someone should write a book about this stuff.