scout05

Regular

Good evening,

Just looking for advice to save myself some money

I have been having issues with my no-drive crank slipping, a few months ago I have my bike serviced and since have had issues with the crank, firstly the retaining bolt came lose and fell out, after replacing this a few weeks later the crank slipped which I just sorted on the road side.

A few weeks after this it slipped again and now I can get it to hold at all.

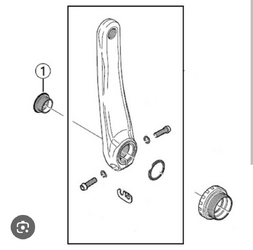

I can't remember what was done during the service but there was something to do with the bottom bracket, I'm not looking to blame just find the issue. Should the thread be flush with the crank (see picture)

I suspect it is just the grooves have worn on the crank as they are only prominent as you can see in the picture and nothing to interlock with on the bottom bracket and in the tight screws have just been holding it in the place the last few months?

I can't find a picture to see what the crank should look like

Just looking for advice to save myself some money

I have been having issues with my no-drive crank slipping, a few months ago I have my bike serviced and since have had issues with the crank, firstly the retaining bolt came lose and fell out, after replacing this a few weeks later the crank slipped which I just sorted on the road side.

A few weeks after this it slipped again and now I can get it to hold at all.

I can't remember what was done during the service but there was something to do with the bottom bracket, I'm not looking to blame just find the issue. Should the thread be flush with the crank (see picture)

I suspect it is just the grooves have worn on the crank as they are only prominent as you can see in the picture and nothing to interlock with on the bottom bracket and in the tight screws have just been holding it in the place the last few months?

I can't find a picture to see what the crank should look like

to CC

to CC