Thanks all. I suspect I have been too cautious with the tightening. Perhaps I should fully tighten (until the crank won't rotate), and the slacken off. This will presumably ensure that the bearings are pushed fully 'home'.

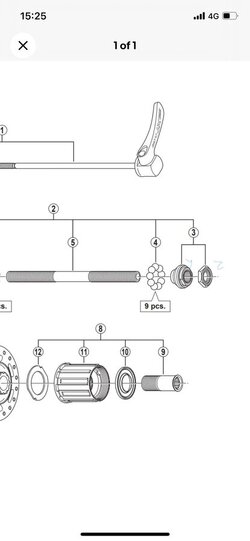

Ajax Bay - there two bearing, each with 9 balls enclosed in a race. I replaced one set.

Jody - I didn't undo the drive side - it wouldn't budge. That's why I replaced like-for-like. If I'd have been able to get both sides off, I'd have put a canister in.

Some great tips everyone - I'll have one more go before removing the bearings. There's a chance I suppose that one of the bearings has failed. Unlikely, but can't be discounted.

Still disconcerted by your narrative.

"

if I'd been able to get both sides off" Sorry? Take off the lock nut, spacer and seal/cone from the left side. Pull the axle out 'complete' from the right side (through the freehub (assumed)), taking care to catch all the balls. Access to "both sides".

"

cannister" - assume you mean a set of caged balls. These offer no better bearing effect: you're well off with loose balls and dollops of grease. With the axle (complete with one locked on cone and locknut)

out you can clean everything and insert new bearings (balls).

"

too cautious with the tightening" All that done screw the LH cone on by hand till finger tight and then back off a quarter turn (assume QR). Lock; like you mean it.

"

a chance that one of the bearings has failed" - do you mean one of the balls has broken on the RHS (which you have failed to access)?

You will know by spinning the wheel in your hand whether this is the case.

I, like you ("

I can't say I understand your point fully"), don't think

@Jody 's cunning idea has merit. I just don't see the mechanism for the effect they describe.